The retrofitting of an iconic department store

Granted planning consent in 2021 and due for completion in 2025, the iconic former House of Fraser department store on Oxford Street is well on its way to being reimagined as a vibrant, mixed-use development. We take a look at what the team has done to enable the adaptation of this beautiful building and ensure its future viability.

Originally designed by the architect Louis Blanc, the 1930s Art Deco style building sits on a prominent site on Oxford Street, with additional elevations along Old Cavendish Street, Henrietta Place and Chapel Place. Over time, through a series of unsympathetic alterations and modifications, the elegance and considered detailing of the original shopfronts have been obscured.

Jumping forward to now, the team is employing a retrofit-first approach, with sustainability at the heart of the proposals, targeting BREEAM Excellent and WELL Gold Certification. By paying particular attention to how to sensitively upgrade the thermal performance of the external envelope through replacing inefficient glazing on the retained facades and specifying high performance, thermally efficient build-ups for any new build areas, the team has managed to go beyond the targets set at early stage.

The iconic façade

The building had previously been covered in protective netting because the facade was suspected to be suffering from Regent’s Street disease as the spandrel panels had cracked. This is a condition where the steelwork supporting a stone facade has corroded, causing the stone to crack and fall off. An inspection by the structural engineers, Civic Engineers, revealed that the steelwork was in good condition, with cracks occurring next to the steel flanges of horizontal support beams at floor level, meaning very little work was needed.

One of the key questions was to what extent the existing building should be insulated as, due to this method of affixing the stone façade, any damp within the walls could cause corrosion of the brackets, which would make the stone façade unsafe. The decision was therefore taken not to insulate the retained walls, due to the risk of condensation. As a result, the focus has been on improving inefficient glazing, which formed a large percentage of the external envelope.

Below is an overview of the façade approach:

Floors 1-4: Historic walls and stone spandrels retained and repaired. Existing, inefficient glazing on the retained façades has been removed and replaced with energy-efficient glazing units which achieve a U Value of 1.4, thus reducing energy losses.

At fifth floor level, due to the poor condition of the façade it was not viable to preserve the existing building fabric above the window bays, so the opportunity was taken to upgrade the thermal performance of the walls to 0.15 using insulated construction. Inefficient glazing was also replaced with energy efficient units as per floors 1-4.

Floors 6-8 – These new build levels have been designed using appropriate modern construction techniques with walls targeting a thermal performance of 0.15. These levels also feature new energy-efficient, solar-coated double-glazing units, reducing energy losses and unwanted solar gains in summer and resulting in reduced heating and cooling demand.

Roof terraces: The roof buildups have been designed to be thermally efficient, achieving a U Value rating of 0.14.

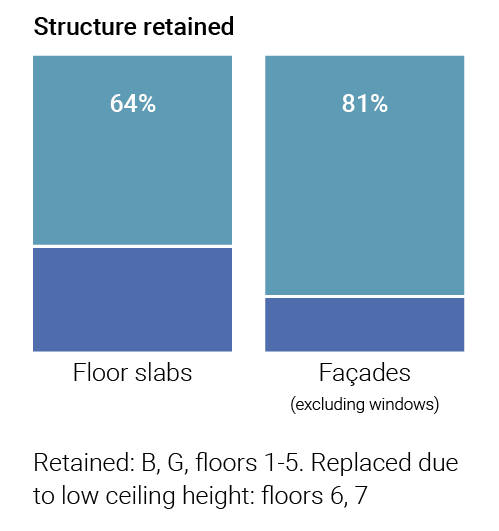

The existing structure

The existing sixth and seventh floors had very limited floor-to-ceiling heights, so these were deemed to be untenable for future use and therefore needed to be replaced.

Three new-build floors will crown the development (just one more than in the existing building so as to avoid the need to strengthen the columns within, which would have cost a lot of time, money and carbon). The replacement floors at levels six and seven will provide large, flexible, commercial office floor-plates and the new eighth floor will house a 1,250sqm restaurant boasting 360 degree views across London, with access to external terraces.

Source: Civic Engineers

More structure has been retained at the top of the building than the replacement of two floors would suggest, thanks to urban mining and the subsequent reuse of some of the columns. The central section of the fifth floor has been retained, including the sixth-floor slab. The columns on the perimeter of the remainder of the fifth floor were double height, so are being moved to support the roof slab over the new eighth floor. Whilst the seventh floor and roof slabs have been removed, most of the columns supporting the seventh floor have been kept and will be extended to create a deeper floorplate.

Additional urban mining means that 40 tonnes of pre-war steel from the existing structure is being reused in FORE Partnership’s TBC.London development - a low carbon office retrofit at Tower Bridge - in what is believed to be an industry first.

Other interventions

In addition to the fabric improvements outlined above, 90m2 of solar photovoltaic (PV) panels have been introduced, which will provide renewable energy to offset carbon emissions. Air-source heats pumps will be used for the new-build extension, which will better the 35% carbon reduction as outlined in the London Plan 2016 and high efficiency, ultra-low NOx emission boilers and air-cooled chillers in the retained element of the building will achieve a carbon reduction in excess of 50% over the baseline carbon emissions.

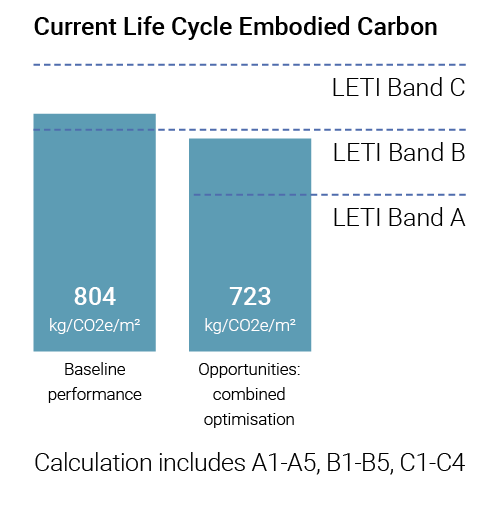

Calculations show that the work to date achieves the LETI 2020 Design Target for Offices (Band C), however the team is exploring options to better this and achieve LETI Band B.

It’s important to note that we are fortunate to be working with a client who has taken a long-term approach to the sensitive reimagining and repositioning of this historic department store. Consequently, the focus has been on the creation of long-term value, by delivering a highly adaptable, sustainable and healthy building.

Subscribe to our newsletter to stay up to date with all of our news and stories.